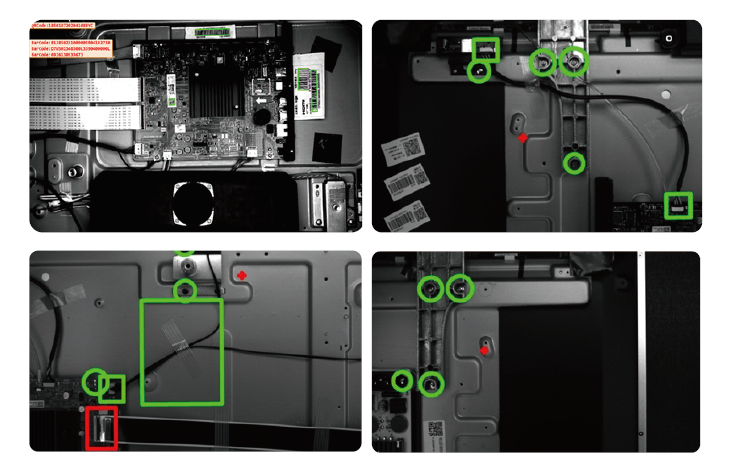

In-Line AOI Inspection Equipment (ET-5000) is based on RegemMarr's core AI algorithm technology, combined with multiple sets of high-resolution cameras and optical systems. It is used for in-line AOI visual inspection of defects in smart screens, smart TVs, displays, all-in-one PCs, etc. It enables product assembly process inspection and fully automated detection, supporting on-the-fly inspection without stopping the production line, helping enterprises reduce costs and improve efficiency.

Advantages of In-line Inspection Equipment

Continuous Flow Inspection

Supports non-stop production line detection

Increases production capacity by 55%

Multi-Line Compatibility

Works with belt conveyors, roller conveyors, and pallet conveyor systems

| Product Name | Functional Parameters | ||

|---|---|---|---|

Inspection Content | Missing Screw Interception | ||

| Unplugged Snap-Fastener/Wire-Clip Interception | |||

| Missing Wiring Process Tape Interception | |||

| Inspection Speed | 10-25 seconds/pcs | ||

| Inspection Range | 32"~43",49"~65", ≥ 65"U | ||

| Inspection Metrics | Accuracy ≥96.5%, Over-Inspection Rate ≤3%, Missed Inspection Rate ≤0.5% | ||

| Information Technology Support | SCADA;MES;CIM | ||

| Labor Savings | Saves 3-6 Operators | ||